1. Yintoni isilinda esidityanisiweyo?Umgqomo udityaniswe ngokuthe ngqo kwii-caps zokuphela kwaye amachweba adityaniswe kwi-barrel.Idlala langaphambili intonga ibotshelelwa ngokubanzi okanye ifakwe kwi-cylinder barrel, evumela ukuba indibano yepiston yentonga kunye nezitywina zentonga zisuswe ukuze zisebenze.Iisilinda ezidityanisiweyo zehydraulic zinenani leenzuzo ngaphezulu kweesilinda zentonga.Nangona iisilinda zeentonga zokubopha zinokungabizi kakhulu ukuvelisa, zihlala zijongwa njengezinto "ezingekho kwishelufu" kwaye zinokhetho olulinganiselweyo malunga nokwenziwa ngokwezifiso.Kananjalo azihlali ixesha elide kuneesilinda ezidityanisiweyo.Iisilinda zomzimba ezidityanisiweyo zinokuthi zenziwe ngobunjineli bokwenza izinto ezithile.Iisilinda ezidityanisiweyo nazo zineepakethi zokutywinwa eziphezulu, ezinokunceda ukwandisa ixesha lokuphila kwe-cylinder kwaye kunokuba luncedo xa i-cylinder iya kusetyenziswa kwiindawo ezibandakanya ukungcola kunye nemozulu.Ngobuhle, iisilinda zomzimba ezidityanisiweyo zineeprofayili ezisezantsi kunezisilinda zentonga kwaye zinokuphucula inkangeleko yesixhobo esisetyenziswa kuso.Kuba zimxinwa kunentonga yeqhina elilinganayo, iisilinda ezidityanisiweyo zehydraulic zisebenza kakuhle kwizicelo apho isithuba siyinto.

2. Indlela yokulawula umgangatho we-welding ngexesha lemveliso yobuninzi?

Izixhobo zokuwelda;Lungiselela isampuli welding ngokungqongqo ngokweemfuno inkqubo kwangaphambili: Preheating, ukuwelda, ukugcinwa ubushushu, kunye nokulungiselela isampuli welding.Kwaye ukwenza ikhadi lenkqubo ye-welding ukubonelela ngesiseko sokuphunyezwa kwe-welding;Izixhobo ze-welding, i-welding wire kunye ne-welding gas zizinto ezifanayo, ukusebenza okuzinzileyo, ukucoceka kwegesi ephezulu, kunye nemilinganiselo echanekileyo;Umntu wokuwelda, kufuneka abe nesatifikethi se-welder;Uvavanyo lwe-welding, olufana novavanyo lwe-weld bead kunye novavanyo lwe-ultrasonic ukujonga umgangatho we-welding.

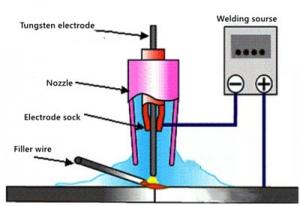

3. I-gas shielded welding inokwahlulwa ibe yi-inert gas shielded welding (TIG welding), i-gas shielded welding (i-MAG welding) .Ngokucacileyo, i-argon isetyenziswa kakhulu ngenxa yexabiso layo eliphantsi, ngoko ke igesi ekhuselweyo yentsimbi ekhuselweyo yentsimbi ikwabizwa ngokuba yi-argon arc welding.I-Tungsten inert yegesi ye-welding yinkqubo ye-welding apho i-tungsten okanye i-tungsten alloy isetyenziswe njengezinto ze-electrode, kwaye i-arc eyenziwa phakathi kwe-electrode kunye nesiseko sezinto ezisisiseko sisetyenziselwa ukunyibilikisa izinto ezisisiseko kunye nokuzalisa ucingo phantsi kokhuseleko lwegesi ye-inert. .

I-TIG, eyaziwa ngokuba yi-Gas Arc Welding (GTAW), yindlela yokwenza i-Arc phakathi kwe-electrode ye-Tungsten kunye nesiseko sesinyithi phantsi kokhuseleko lwegesi engasebenziyo ukwenzela ukuba isiseko sesinyithi kunye ne-welding wire material inokunyibilika kwaye emva koko idityaniswe.Ibandakanya i-DC TIG welding kunye ne-AC TIG welding.

I-DC TIG welding ithatha i-DC arc welding power source njengomthombo wamandla we-welding, enamandla kakhulu angalunganga kunye nesiseko esilungileyo.Isetyenziswa ikakhulu ukuwelda intsimbi engatyiwa, titanium, ubhedu kunye nengxubevange yobhedu.Umthombo wamandla we-welding we-AC TIG welding ivela kwi-AC arc, kwaye i-anode kunye ne-cathode yezinto ezisisiseko zitshintshile.I-EP polarity electrode overheating inokususa isiseko semathiriyeli ye-oxide layer, isetyenziselwa ikakhulu i-aluminium, i-magnesium, kunye nenye i-alloy welding.

Xa i-TIG (GTAW) i-welding operation, i-welder ingaba i-welding gun esandleni esinye kunye nocingo lwe-welding esandleni, olufanelekileyo ekusebenzeni okuncinci kunye nokulungiswa kwe-welding manual.I-TIG inokudityaniswa phantse zonke iintsimbi zemizi-mveliso, inika imilo elungileyo yokuwelda, i-slag encinci kunye nothuli lunokusetyenziswa ngokubanzi kwipleyiti yentsimbi ebhityileyo nengqindilili.

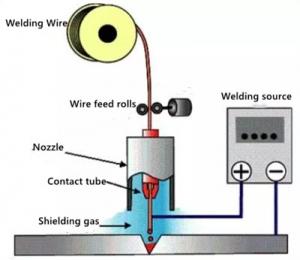

I-MAG (i-Metal Active Gas) I-Welding isebenzisa i-CO₂ okanye umxube we-argon kunye ne-CO₂ okanye i-oxygen (i-Active Gas).I-welding ye-CO₂ gas ngamanye amaxesha ibizwa ngokuba yi-CO₂ arc welding.Izixhobo ze-MIG kunye ne-MAG ze-welding zifana nokuba ziyakwazi ukutyiswa ngaphandle kwetotshi nge-finder yocingo oluzenzekelayo kwaye zifanelekile kwi-welding ngokuzenzekelayo, ungakhankanyi i-welding manual.Umahluko ophambili phakathi kwabo ulele kwigesi ekhuselayo, eyokuqala ikhuselwe ngokubanzi ngegesi ye-argon ecocekileyo, ilungele ukuwelda izinyithi ezingenayo i-ferrous;I-MAG welding ikakhulu isebenzisa i-CO₂ gas, okanye i-argon exutywe i-CO₂ igesi esebenzayo, oko kukuthi i-Ar + 2% O₂ okanye i-Ar + 5% CO₂, ilungele ukuwelda intsimbi yamandla aphezulu kunye nentsimbi ephezulu ye-alloy.Ukuze kuphuculwe ukusebenza kwenkqubo ye-CO₂welding, i-CO₂+Ar okanye i-CO₂+Ar+O₂ igesi edibeneyo okanye i-flux-core wire ingasetyenziswa.I-MAG welding ibonakaliswe ngesantya sayo esikhawulezayo se-welding, ukusebenza kakuhle kokuqaliswa kwe-arc, i-pool enzulu, ukusebenza kakuhle kwe-deposition, inkangeleko enhle, ukusebenza okulula, ilungele i-high-speed pulse MIG (GMAW) welding.

Ukukhawuleza kuzibophelele kwi-R&D kunye nokuveliswa kweiisilinda zehydraulickunye neenkqubo zehydraulic, ukunceda abathengi kunye nokubonelela abasebenzi ngobomi obungcono.Ukuza kuthi ga ngoku, siye sanceda amawaka abathengi kwihlabathi liphela-ukubonelela ngobuchwephesha bobuchwephesha be-hydraulic cylinder kunye noyilo lwenkqubo kunye neenzuzo zokukhuphisana.

Ixesha lokuposa: Sep-16-2022